1,5 m

Span

1600 g

RTF

48 g/dm²

Wing load

-STL files

-G-codes

-3mf bambu studio

-Scheme design

ASSEMBLY GUIDE

SPECIFICATIONS

PRINTED WEIGHT 1100g

TAKE OFF WEIGHT 1600g

STALL SPEED 23km/h

WING LOADING 48g/dm²

WING SPAN 1500mm (59")

WING SURFACE 33dm²

WING ASPECT RATIO 6,8

LENGTH 1080mm

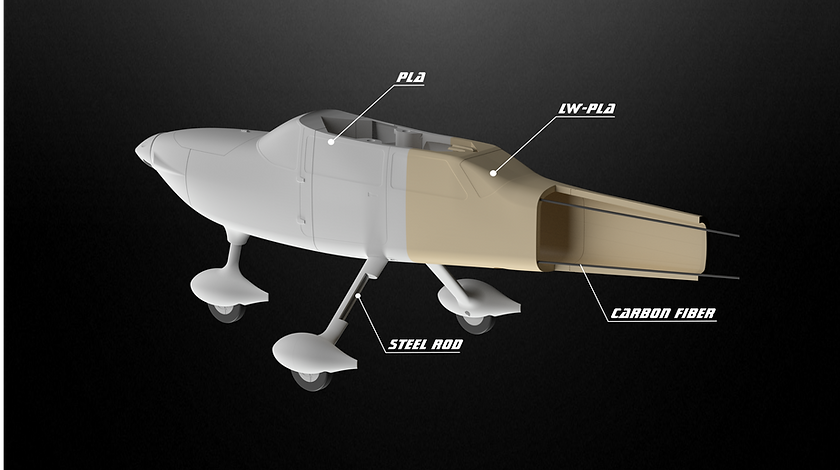

Reach new heights with the Skyward, a fully 3D-printed RC aircraft designed to deliver exceptional strength, versatility, and forgiving flight characteristics for pilots of all skill levels. The Skyward features an advanced hybrid construction that combines PLA, LW-PLA, and carbon fiber reinforcement to achieve an outstanding strength-to-weight ratio. This material combination allows the airframe to remain lightweight while maintaining the structural rigidity required for reliable and durable performance, making it ideal for both relaxed cruising and demanding flight conditions. Designed with stability as a priority, the Skyward incorporates a high-wing configuration paired with a nearly rectangular wing planform, providing inherently predictable and forgiving handling. This layout makes the aircraft exceptionally easy to fly, offering smooth control response and excellent low-speed behavior. Integrated flaps significantly reduce landing speeds, allowing for safer and more controlled approaches, even in tighter flying areas. To enhance ground handling and landing performance, the Skyward includes an interchangeable front suspension system featuring two distinct design concepts. Pilots can easily swap between configurations depending on their flying environment or personal preference, ensuring optimal shock absorption and operational flexibility without adding unnecessary complexity. As a fully 3D-printed aircraft, the Skyward embraces modern manufacturing techniques, enabling precise part production, straightforward assembly, and easy maintenance or part replacement when needed. Every component is designed to balance print efficiency, structural integrity, and aerodynamic performance. Whether you're looking for a stable and confidence-inspiring trainer or a reliable everyday flyer, the Skyward delivers a refined combination of innovation, durability, and flight stability.

HYBRID DESIGN

SCALE DETAILS

SHOPPING LIST

ALL THE COMPONENTS THAT YOU HAVE TO BUY TO FLY THE AIRPLANE

3D PRINTER

MIN PRINTING VOLUME - 200x200X200 (X,Y,Z)

NOZZLE DIAMETER - 0,4 mm

Recommended

FILAMENT

QUANTITY - 500g (LW-PLA) 600g (PLA)

TPU (20g) ABS (13g)

Recommended

ECLIPSON HIGH POWER PACK

SERVOS NEEDED - x7

Recommended

BATTERIES

VOLTAGE - 11,1V (3S or 4S)

CAPACITY - 2200 mAh

Recommended

BAT5

RADIO CONTROL SYSTEM

MIN CHANNELS - 8CH

Recommended

OTHER PARTS

-PUSH RODS - D1,2mm(min length 130mm) 7units

-PUSH RODS CONNECTORS 6units

-CF TUBE - D10mm (Length 500mm) 1unit

-CF TUBE - D8mm (Length 500mm) 2units

-CF ROD - D2mm (Length 490mm) 4units

-STEEL ROD D3mm (Length 230mm) 2units

-BOLT - M3X40mm (with nut) 2units

-BOLT - M3X20mm 4units

-BOLT - M3X8mm 4units

-SERVO LEAD EXTENSION (min 500mm) 4units

-SERVO LEAD EXTENSION (min 200mm) 1unit

-SCREW - M2X8mm (approx.) 40units

-GLUE - cyanoacrylate

-RUBBER BAND- L50mm (approx.)

-VELCRO

Recommended